Operator type 120

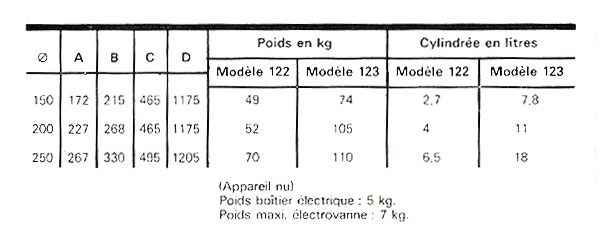

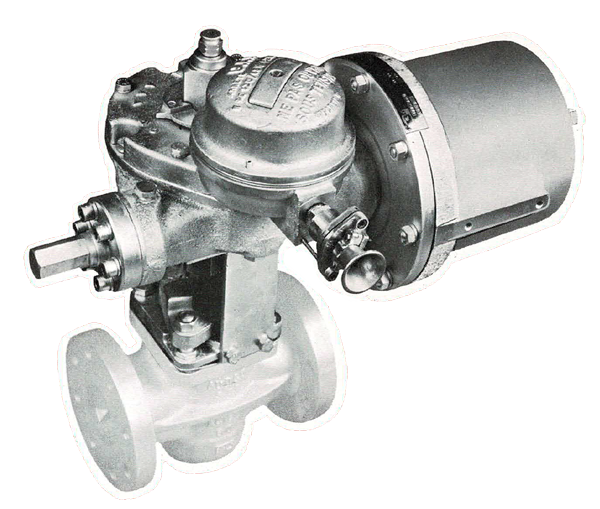

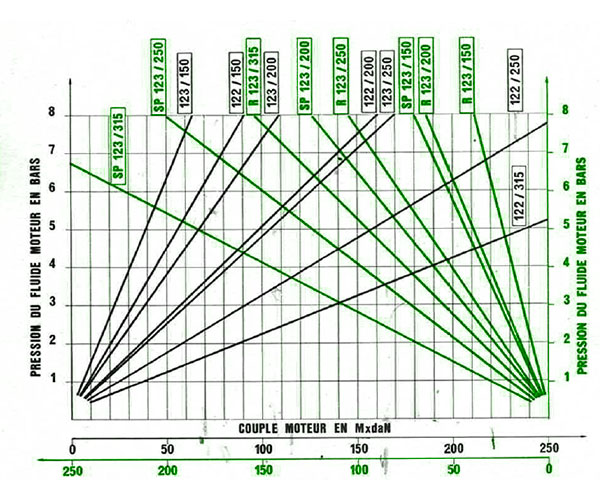

The Type 120 operator is used for torques ranging from 50 to 250 m kg. It consists of a sealed housing containing the mechanisms, allowing for the adaptation of a wide range of cylinders. This enables achieving all intermediate torques and using a driving fluid pressure ranging from 3 to 420 bar. For normal operating pressures, this operator features balanced piston faces and no rod packing.

Definitions

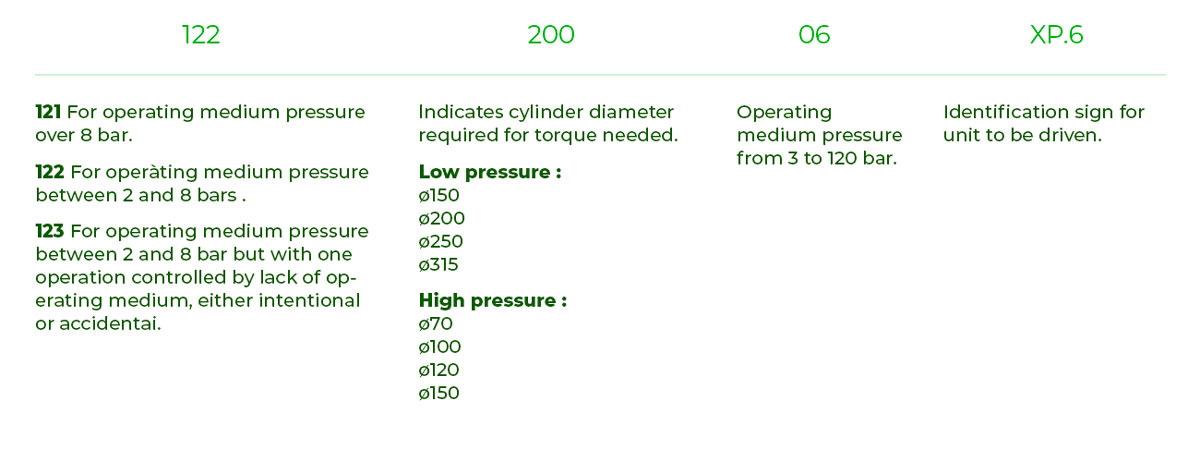

There are numerous models for this type of operator. Each is defined by a four-number symbol:

Example :

Characteristics

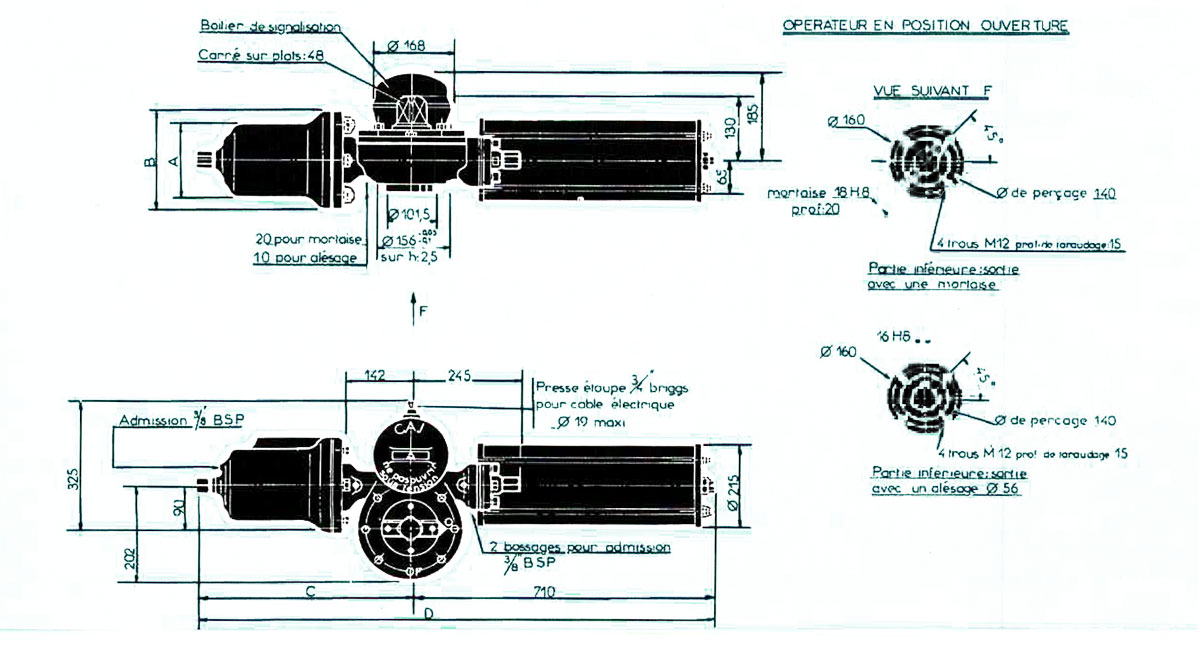

This operator consists of a sealed housing containing motion transformation mechanisms (sector gear rack, reaction stop, bearings, etc.). The control cylinder adapts to this housing via a flange. The piston of this cylinder, made with two elastomer cups tightened by two flanges, is connected to the rack by a nut. A cover, holding the internal elements, seals the housing and is topped with a position indicator integrated with the sector.

Technical Specifications

The housing is made of sealed cast steel or steel depending on the model. Cylinders for fluids with pressures below 8 bars are cast iron, while the rack and piston are made of semi-hardened steel. Depending on models and applications, the sector may be single or dual-part, made of GS cast iron, semi-hardened steel, or stainless bronze, with seals of neoprene or perbunan.

Equipment and Special Models

The Type 120 operator can be provided, upon request, with control or feedback accessories. The minimum passage section for these accessories should be 10 mm. Electrical or pneumatic signaling contacts are also available upon request (see Type 620 manual).

High-Pressure Version

By adapting special cylinders, the Type 120 operator can handle all gaseous or hydraulic fluids up to 120 bar pressure. Refer to the adjacent table for details. (Request specific plans or manuals.)

Note : like all other types in the "SUPER" series, the Type 120 can be submerged after appropriate protection and modifications.