Thermal Fuse Plugs

For compressed air or hydraulic circuits

The technology of thermal fuse plugs is used to release a control fluid to ensure a safety function at a defined temperature.

Depending on the application, this ensures the safety of installations before they become unusable.

Here is the translation of the procedure for testing and qualifying CAI thermal fuse plugs by Bureau Veritas:

1. Description of the Thermal Fuse Plug

1.1 Field of Application

1.1.1 The control system for safety valves must, in certain applications (gas, petroleum, ...), be designed so that the valve, actuated by a single-acting or double-acting actuator, moves to the safety position under fire conditions. The control system may include a thermal fuse plug with a melting temperature between 98°C and 104°C. In the event of a fire, the safety valve closes or opens, depending on the application.

1.1.2 Mounting Direction

We recommend orienting the thermal fuse plug downward to ensure that the melted metal does not block the orifices.

1.2 Design of the Thermal Fuse Plug

1.2.1 Two types of thermal fuse plugs have been designed for these applications (plans No B-W-08 and C.20699). The plug body is made of either stainless steel or zinc-plated steel. The seal is made of Viton. The fusible metal used is Wl eutectic, with a solid/liquid phase transition temperature of 103°C. The thermal fuse plug is sealed up to a temperature not exceeding 75°C at 6 barG pressure. The thermal fuse plug functions as intended within the temperature range of 98°C to 104°C. The maximum operating pressure should not exceed 10 barG (Pmax).

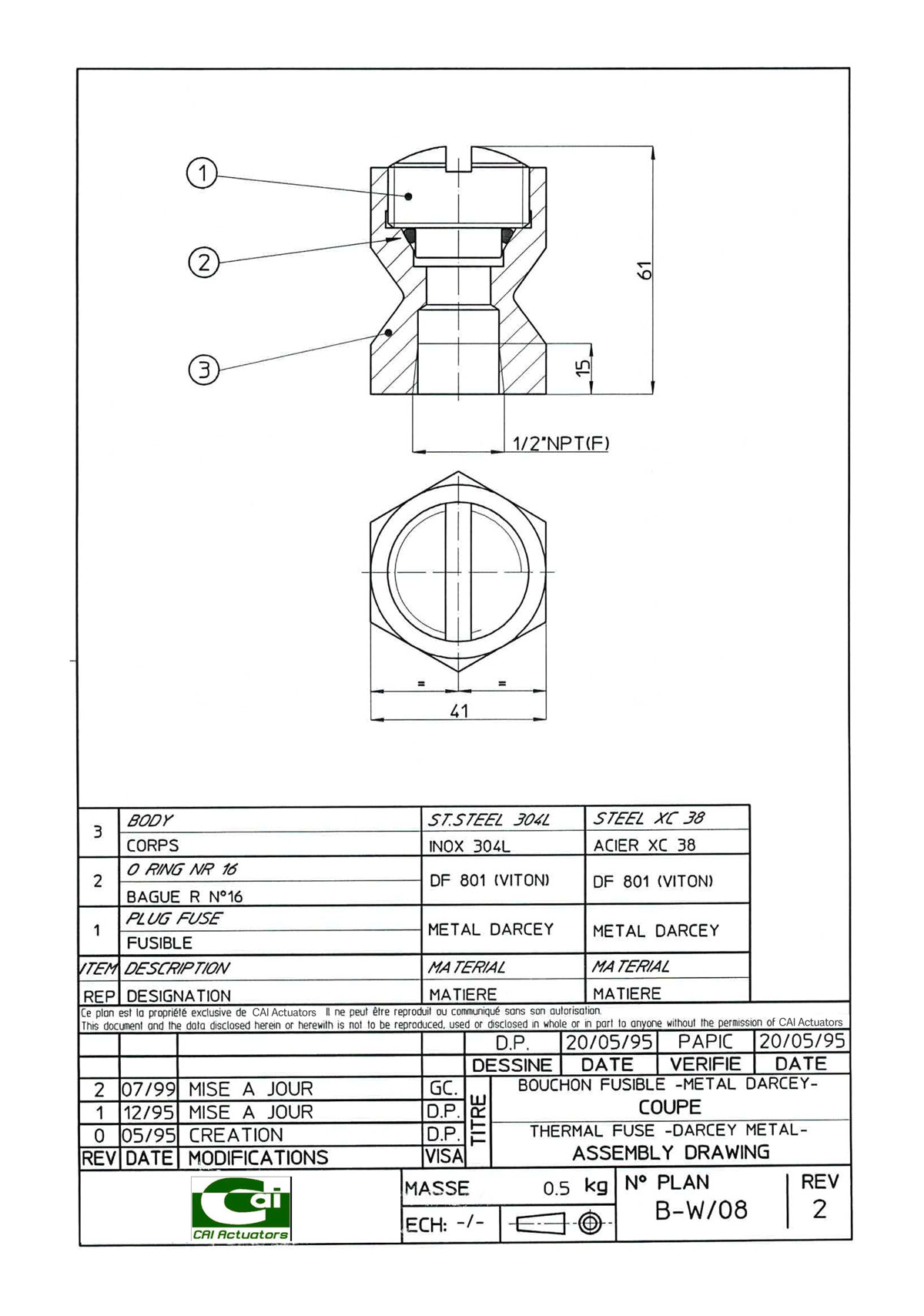

1.2.2 Plan No B-W-08, revision 2

The thermal fuse plug, called "head type," consists of a body (Plan No B-W-06, revision 1), a fusible element (Plan No B-W/07, revision 1), and an O-ring seal.

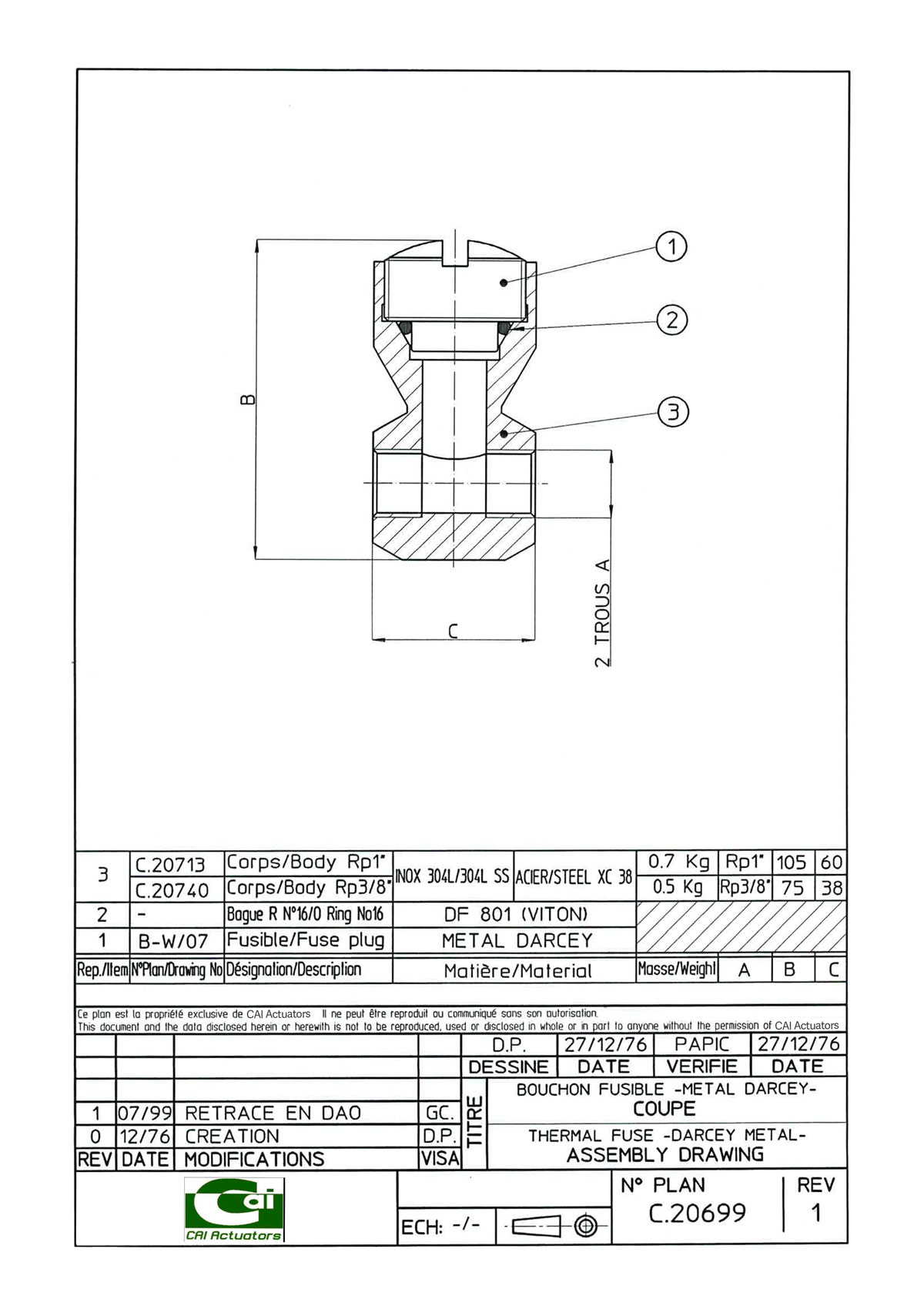

1.2.3 Plan No C.20699 revision 1

The thermal fuse plug, called "in-line type," consists of a body (Plan No C.20740, revision 1), a fusible element (Plan No B-W/07, revision 1), and an O-ring seal.

1.3 Tests

For practical reasons, the functionality of the thermal fuse plug will be validated through qualification tests on the "in-line type." The materials of both variants are identical.

2. Qualification Criteria

2.1 Leakage

The assembly must remain leak-free at 1.5 x Pmax, where Pmax is the maximum operating pressure of the assembly. Leakage will be detected by spraying an active solution (such as Loctite DF9) onto the assembly.

Qualification criterion: No leakage from the thermal fuse plug at 1.5xPmax pressure and at room temperature.

2.2 Melting Temperature

The fusible metal transitions from solid to liquid phase at a temperature of 103°C.

Qualification criterion: The thermal fuse plug must perform its function at the specified temperature.

3. Testing Procedure

3.1 Sampling

Samples will be randomly selected from a batch of approximately 20 thermal fuse plugs. Two assemblies will be used for leakage tests. Five assemblies will be used for temperature tests.

3.2 Leakage Test

Two samples will be tested at 15 barG pressure for 5 minutes at room temperature of 23°C (±2°C). One orifice will be blocked, and the assembly will be pressurized through the second orifice. It will be verified that there is no leakage.

3.3 Melting Temperature Test

3.3.1 Setup

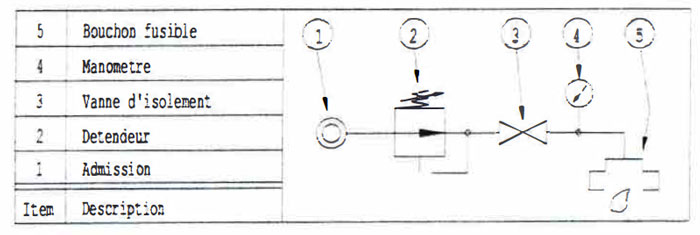

The thermal fuse plug (marking 5) will be connected upstream to a regulator (marking 2) equipped with a pressure gauge (marking 4). The second orifice will be sealed. The assembly will be pressurized to the required pressure, then isolated from the air supply (marking 1) by the valve (marking 3). The thermal fuse plug will then be placed in a ventilated oven.

3.3.2 Testing procedure

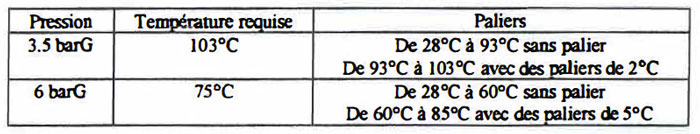

- Pressures: 3, 5, and 6 barG

- Temperatures: see table

- Number of samples: 5 (3 for tests at 3.5 barG, 2 for tests at 6 barG)

Until the fuse plug melts, the pressure gauge will indicate the initial pressure Pl. A drop in pressure indicates that the fuse plug has melted. The temperature will be indicated by a thermocouple placed near the tested fuse plug.

3.4 Testing Equipment

3.4 Testing Equipment

3.4.1 Calibrated pressure gauges, usable ranges 0-11 barG and 0-20 barG.

3.4.2 Calibrated thermometer with a resolution of 0.1 °C.

3.4.3 Active solution (such as Loctite DF9).

4. Bureau Veritas Stamp

For certain applications, thermal fuse plugs tested and approved by Bureau Veritas will be stamped.

5. Annexes

Plans

- B-W/08 revision 2

- B-W/07 revision 1

- C.20699 revision 1

- C.20740 revision 1