A new generation of quarter-turn actuators

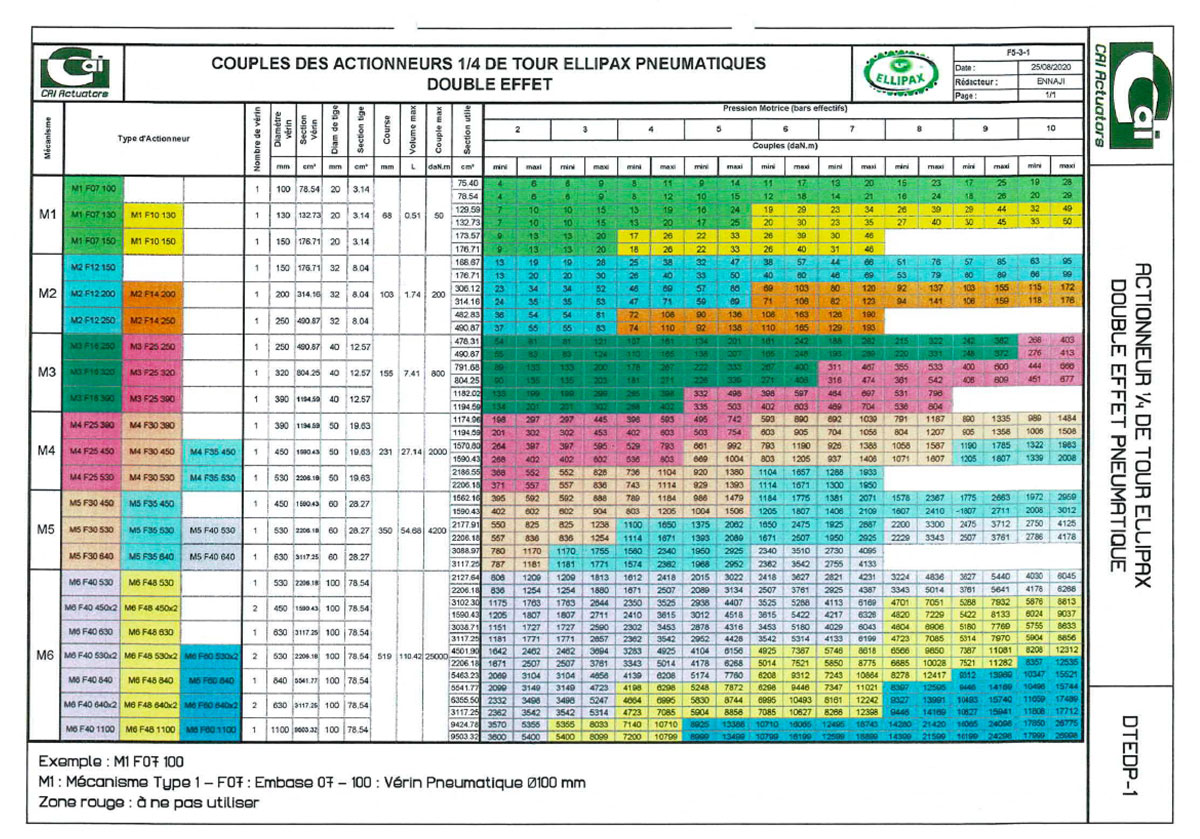

with variable and adaptable torque.

Ellipax is flexible

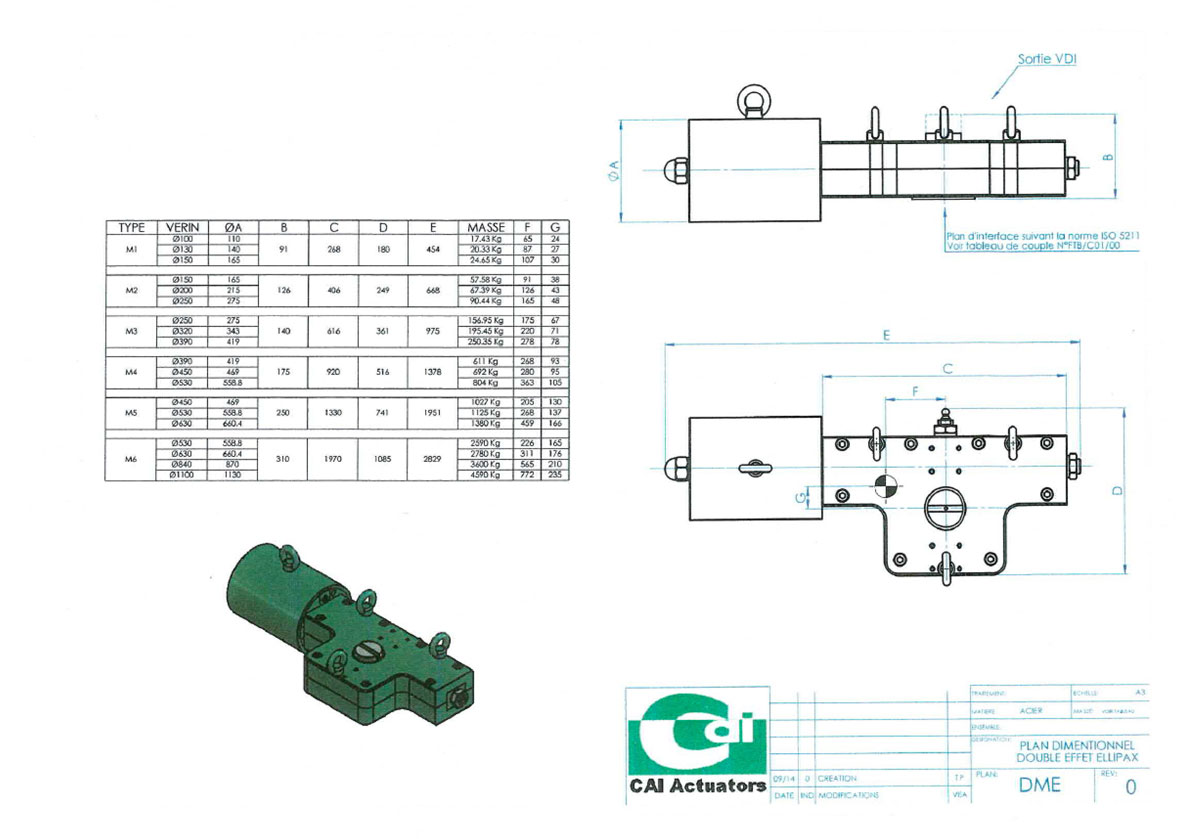

Double-acting pneumatic or hydraulic.

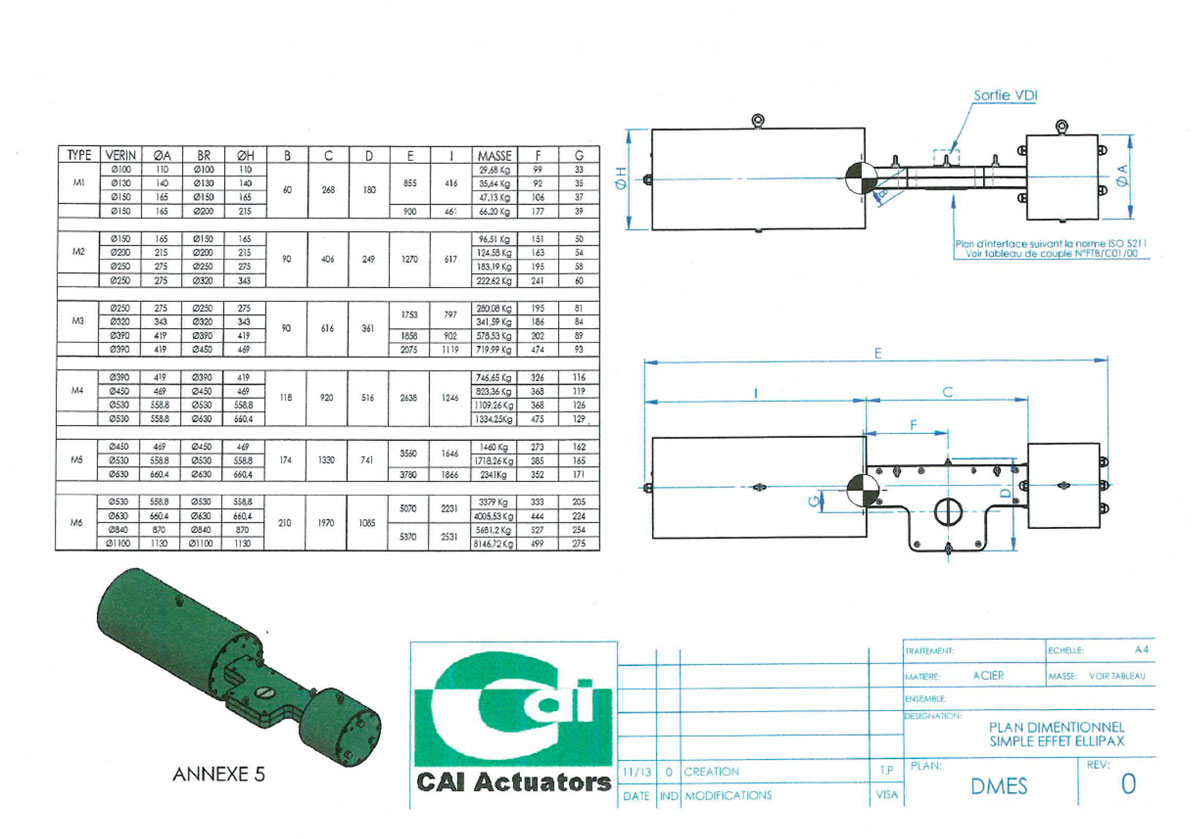

Single-acting with spring or reservoir.

Options

- Manual control

- Limit switch box

- Valve adaptation

- Special applications

- Control systems

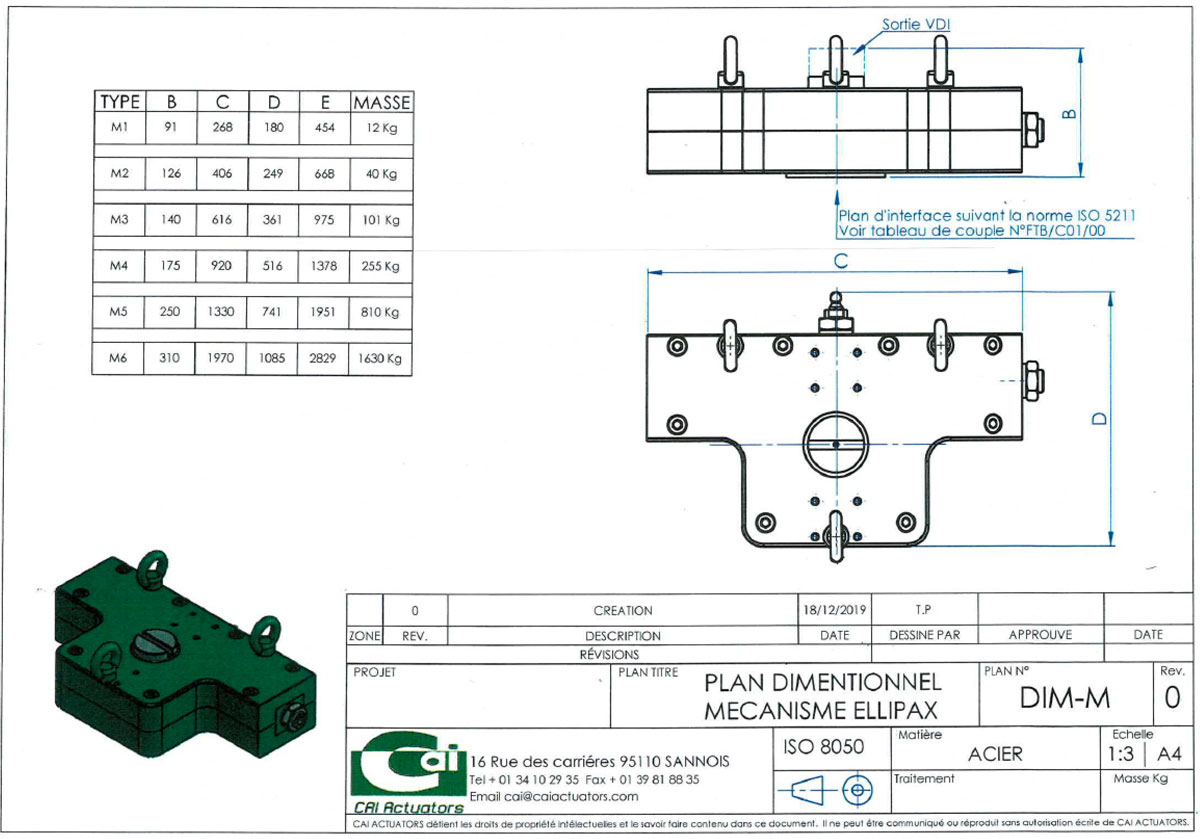

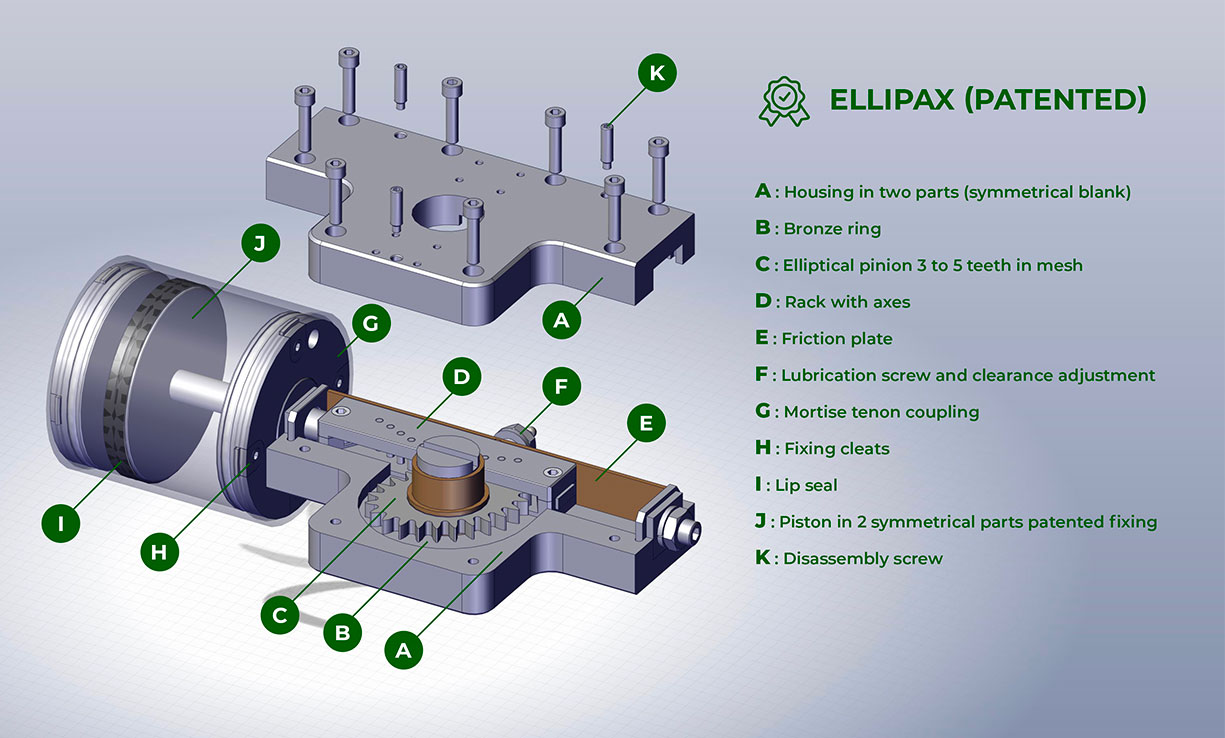

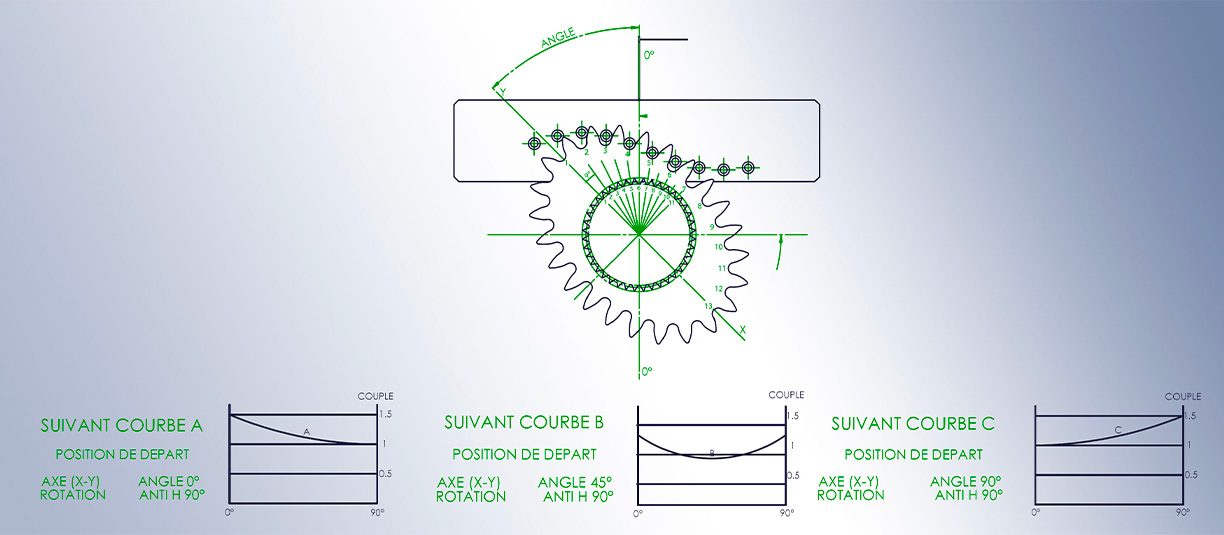

The operating principle of the Ellipax actuator is entirely new and innovative; it is based on the use of an elliptical pinion engaging with patented ground and hardened shafts, arranged on a rectangular rack. ELLIPAX allows for a maximum torque variation equal to R / r = 1.5, providing intermediate positions in line with the torques required by the valves, by changing the position of the elliptical pinion on the splines of the sleeve.

Other advantages of the system

1 | SIMPLE AND ROBUST MANUFACTURE : The housing consists of two ultra-flat symmetrical parts that enclose the entire mechanism. By design, the number of parts is minimized.

2 | INCREASED LIFESPAN : The patented pinion design allows for a number of teeth in mesh varying from 3 to 5, reducing the stress on each tooth.

3 | SIMPLE DISASSEMBLY AND MAINTENANCE : The entire mechanism can be disassembled with a hex key. The cylinders are housed in a groove designed in the halves of the housing and are not bolted.

4 | CYLINDER DESIGN : Thanks to a patented pawl system replacing fasteners, there are no protruding parts on the cylinders.

5 | CENTRAL LUBRICATION : All moving parts, including bronze bearings, are lubricated from a single source.

6 | PRICE : One of the key objectives of product development and design was cost. All parts are optimized for automated machining, quick, and easy assembly.

7 | APPLICATIONS : The most demanding uses, such as offshore, cold, or aggressive environments, are achievable thanks to product design and appropriate materials. (Special steels, INOX316, 17.4PH, ALLOY, etc.)

8 | STANDARDS : All our products meet ISO 9001, ATEX, PED, SIL1 and 2 standards and comply with the 5211 standard for valve adaptation and the Namur VDI/VDE 3845 standard for limit switch box adaptation.