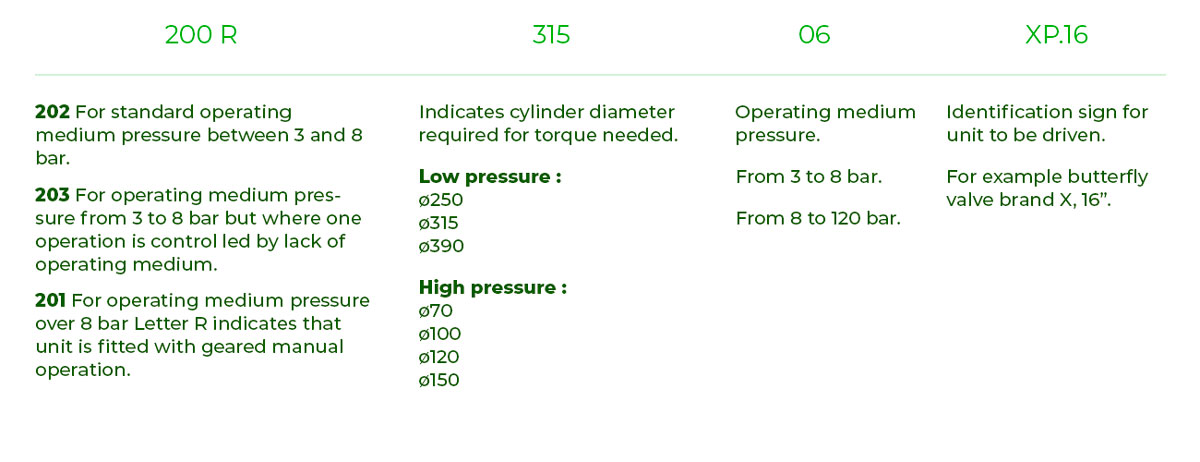

Operator type 200

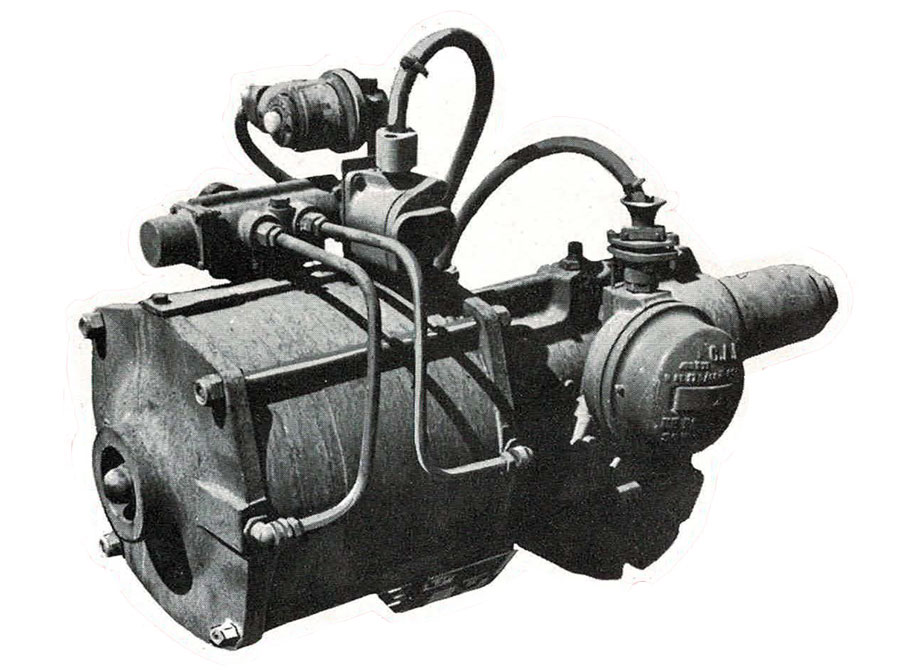

Operator Type 200 is a "compact" series valve actuator with rack and pinion. Positioned between Type 120 and Type 300 in the new range, it is designed for motorizing various valves such as conical, cylindrical, lubricated or non-lubricated spherical valves, as well as butterfly and gate valves.

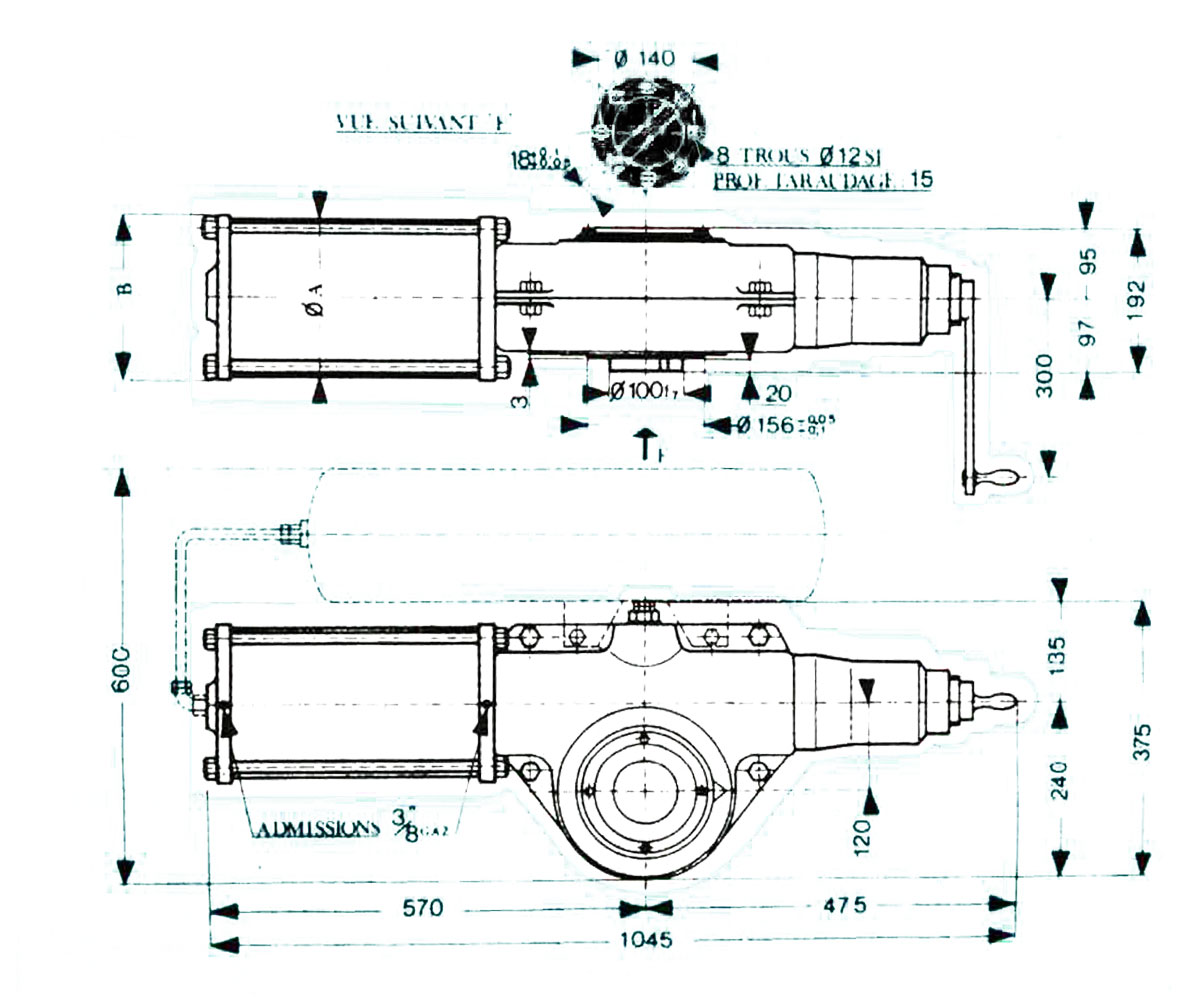

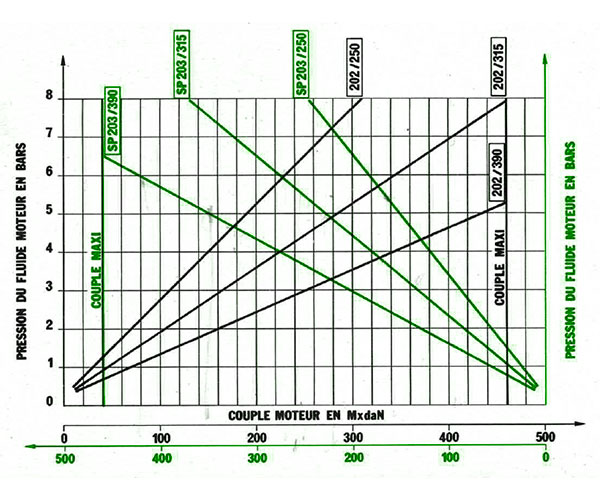

The mechanism's capacity and the adaptation of cylinders based on the driving fluid pressure allow it to generate a torque between 120 and 400 Nm. In normal construction, it rotates 90° plus adjustment, but special elements can extend rotation to continuous 180° or two separate 90° movements. The cylinder and manual operation are symmetrically interchangeable.

Operator Type 200 exerts no radial force on the drive shaft. The driving fluid can be low-pressure air or gas (7 bar) or high-pressure (120 bar) without expansion, or hydraulic fluid. The chemical characteristics of the driving fluid dictate the material of seals and the treatment of internal components.

Definitions

Available on request: signaling contactors and control devices. Installation of devices for automatic valve closure based on specific parameters.

For example :

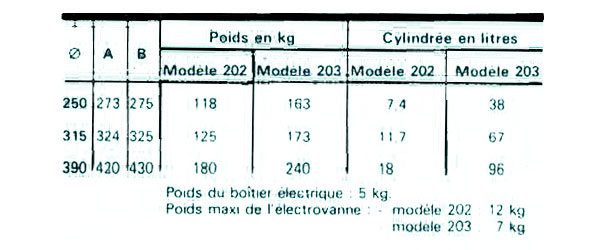

Characteristics

This operator consists of a two-shell housing containing motion transformation mechanisms such as the rack, sector, bearings, and tooth reaction stops. One flange of the housing clamps the cylinder via an adaptation flange. The piston of the cylinder is fixed to the rack by a threaded connection to adjust the stroke during assembly. Two adjustable mechanical stops are provided to position the rotation according to the device being motorized. The drive and fixation are located at the lower part of the assembly, while the position indicator is at the upper part.

Manual Emergency Operation

It is executed by a reversible screw always engaged with the mechanism. The operating lever must be removed during automatic operation. There is no clutch engagement or disengagement required. The assembly is mounted on the other flange of the housing in alignment with the rack. The operator can be supplied without the emergency control.

Technical Specifications

The housing is made of high-quality cast steel. The mechanisms and cylinder parts are made of carbon, manganese, and silicon steel; external moving parts are stainless steel; bearings and pads are bronze; guides are graphite-filled PTFE. All molded seals are made of Perbunan, and cut seals are made of rubberized asbestos in the standard version.

Equipment and Special Models

The Type 200 operator can be supplied, upon request, with control or feedback accessories. The minimum passage section should be 10 mm. Electrical or pneumatic signaling contacts are also available upon request (refer to Type 620 manual).

High-Pressure Version

By adapting special cylinders, the Type 200 operator can utilize all gaseous or hydraulic fluids up to 120 bar pressure. Refer to the adjacent table. Request specific plans or manuals.

Note : like all other types in the "SUPER" series, the Type 200 can be submerged after appropriate protection and specific modifications.