Operator type 110

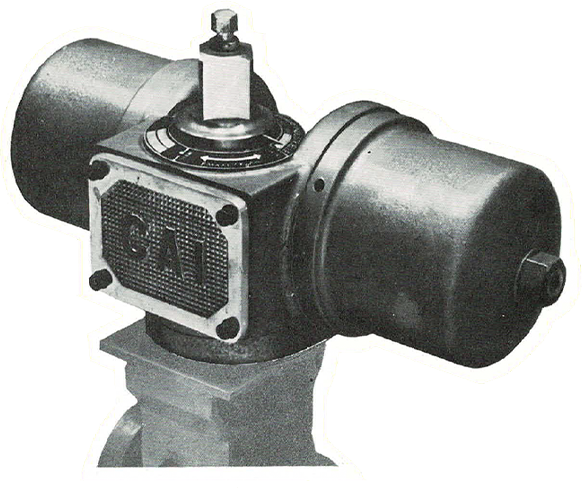

The 110 actuator is consisting of two opposed in line cylinders inside which move two pistons integral with a rack. The rack drives a quadrant which is partly housed within the volume enclosed by the cylinders.

This construction principle which eliminates the need for a linkage rod from the piston, has the following advantages :

- the two driving faces are balanced

- there is no packing-box, therefore no wear

- the lubricant for the internai mechanisms is retained within the movement and its use is virtually zero

- maintenance is negligeable

- dimensions are minimal.

Définitions

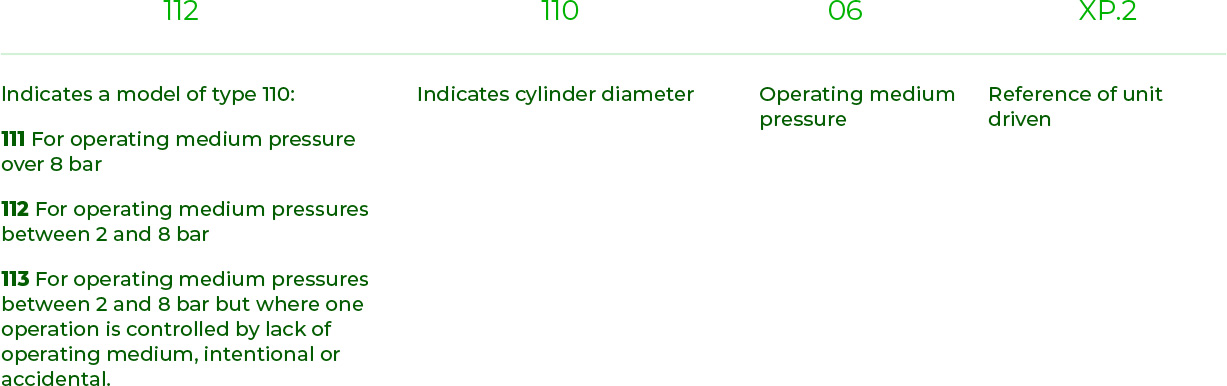

There are several models of this type of actuator. Each is defined by a reference number with four groups :

For exemple :

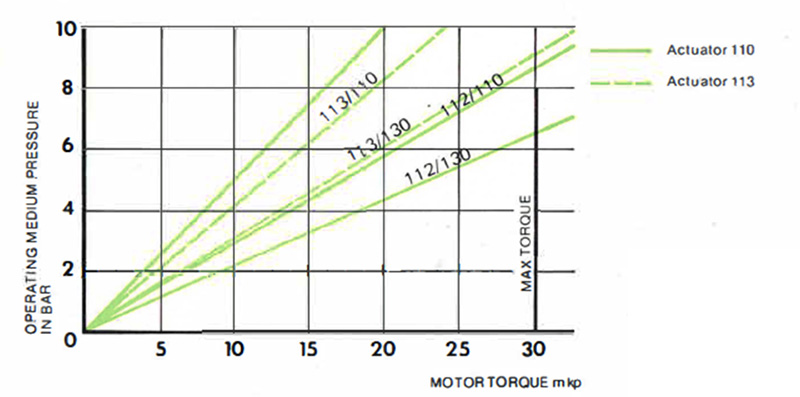

Characteristics

Double-acting SERVO-MOTOR comprising two rnoving cylinders. The two pistons are solidly connected by a rack, the tooth reaction is taken on needle sliders.

- lubrification by soft grease or oil which is retained within the moving parts. (Except for special conditions of temperature or frequency of operation, it is recommended that is should have a viscosity of 3° to 5° Engler at 50 ° C);

- oil drain and fil Ier plug;

- djustable travel I imit stops;

- limit-swich box can be fitted to the body, normally containing 2 switches (1 for the open position, 1 for the closed position) with terminal blocks and out let connections by means of wire or tube;

- manual operating wrench.

Specifications

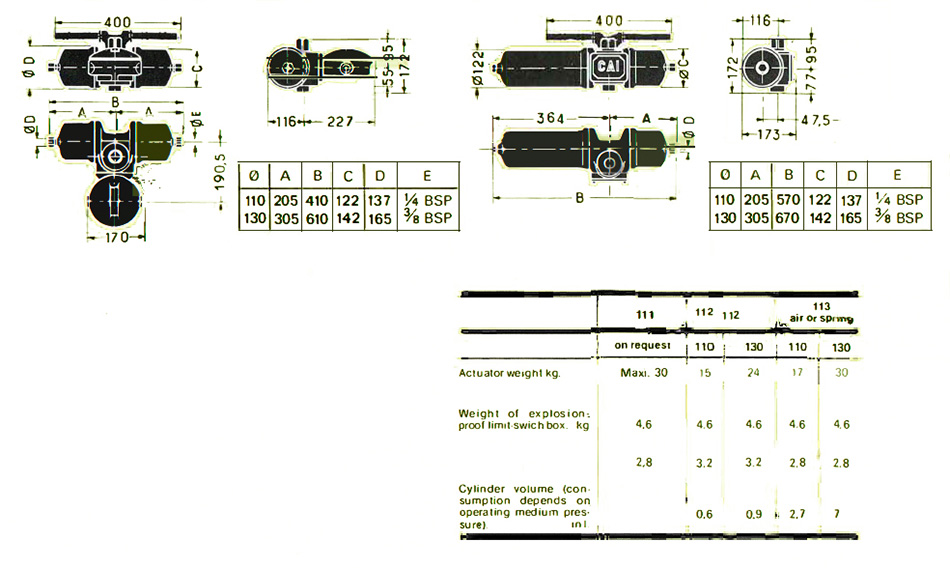

Body of semi-steel, cylinder of aluminium alloy, cast iron or steel, seals and gaskets of neoprene or elastomer, quadrant and rack in half-hard Martin steel. The main drive shaft is of lnoxyda bronze or chrome steel, the guide being of bronze. Ali external linkage elements are hard chromium plated or cadmium plated. External protection is baked enamel or phosphate paint. Operation is not affected by the position of the actuator (but this should be specified with the order). Operating medium inlet 1/4" BSP.