Operator type 400

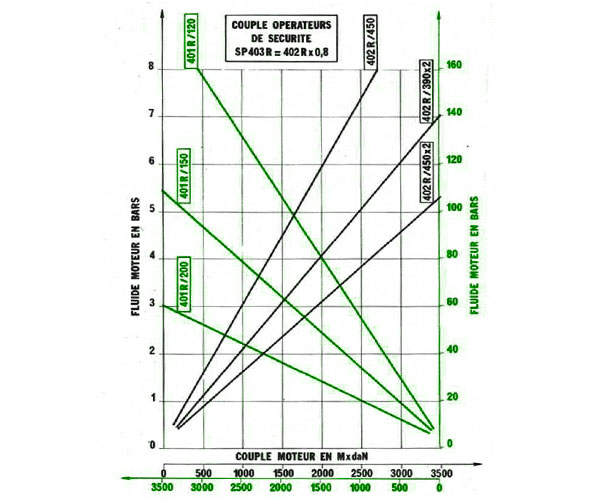

The Type 400 operator is part of the SUPER range of devices capable of directly developing very high torques. It is equipped with a rack and pinion sector gear system with tooth adjustment capability. It operates using gases or liquids ranging from 3 bar to 320 bar, allowing it to generate torques between 2,000 and 3,500 m.kg depending on the size of the cylinders used. The chemical properties of the driving fluid influence the material composition of seals and the treatment of internal components.

Despite these high torques, this operator exerts no radial force on the drive shaft. It is suitable for equipping globe valves, gate valves, ball valves (lubricated or non-lubricated), as well as butterfly valves.

Definitions

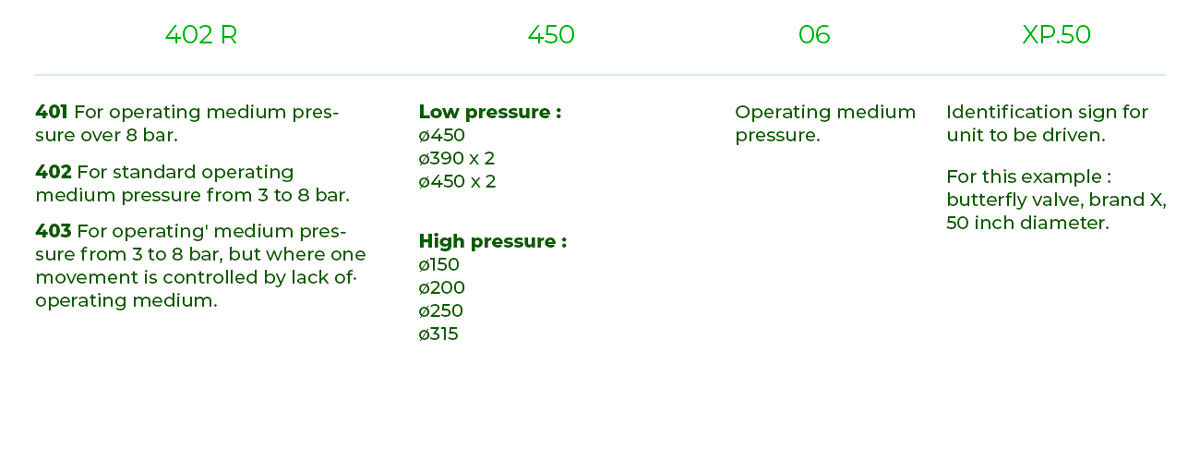

There are several models available for this type of operator. Each model is identified by a four-number symbol:

For example :

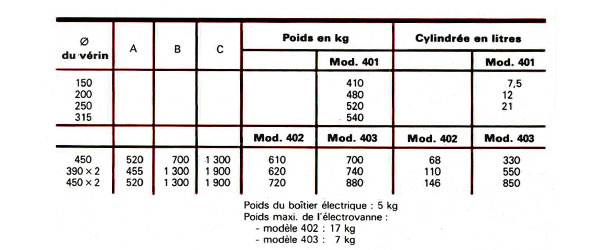

Characteristics

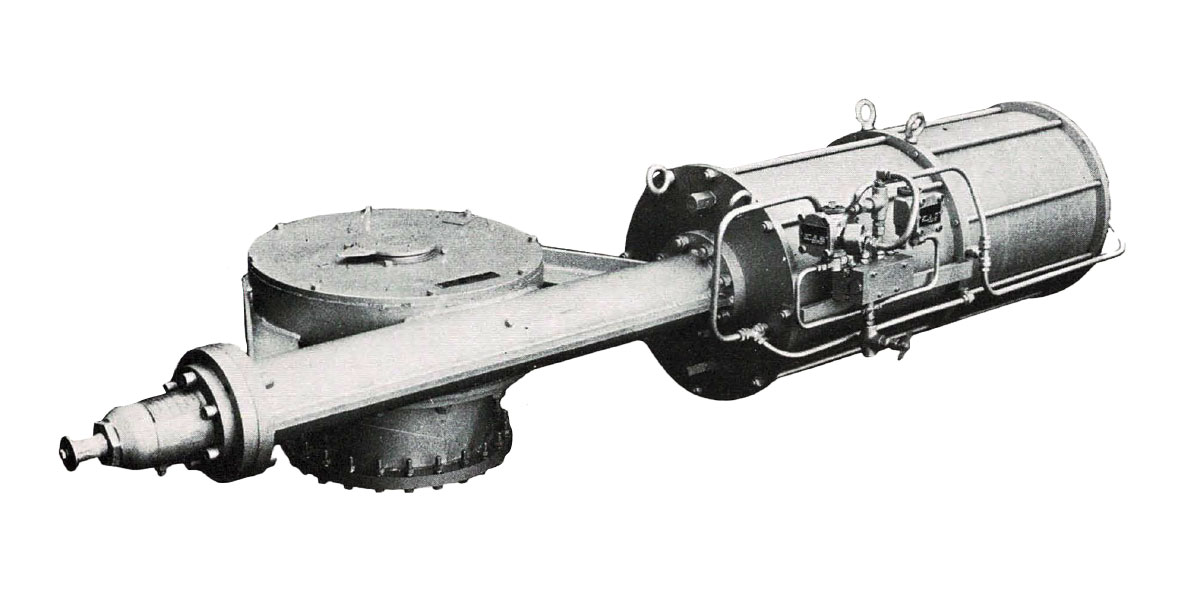

This servo-motor is comprised of a sealed housing containing motion transformation mechanisms such as the rack, sector gear, bearings, and tooth reaction stops. The housing receives the actuator cylinder through an adapter flange on one of its flanges. The piston of the actuator is connected to the rack via a threaded linkage to adjust the stroke during assembly. Adjustable mechanical stops are provided on the actuator to position the rotation according to the motorized component. The drive and mounting are located on the lower part of the assembly, while the position indication is located on the upper part.

Manual Emergency Control

It is operated by a reversible screw always engaged with the mechanism, but the manual operating wheel disengages automatically. It is mounted on the opposite flange of the housing in alignment with the rack. The operator can be supplied without the emergency control.

Technical Specifications

The housing is made of high-quality steel or cast iron. The mechanisms and parts of the actuator are constructed from carbon steel with manganese and silicon, while external moving parts are made of stainless steel. Bearings and pads are self-lubricating bronze, and guides are made of PTFE with MOS2. All molded seals are made of Perbunan, and cut seals are asbestos rubber in the standard version.